QINGDAO NEO GLASS CO.,LTD

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

LAMINATED GLASS --AS/NZS 2208: 1996, CE, ISO 9002

Brief Introduction

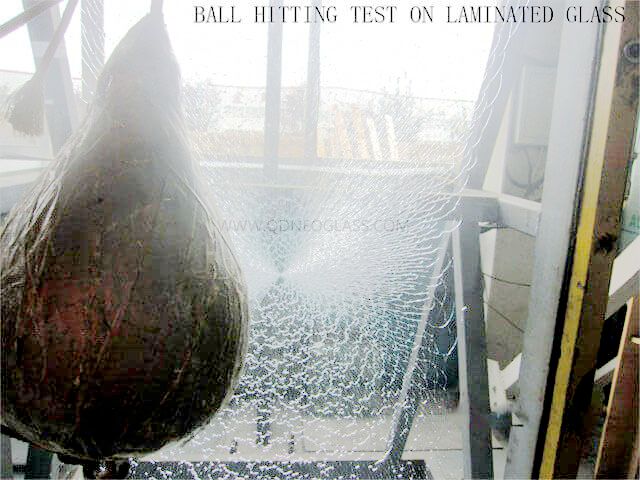

Laminated Glass is one of the Safety Glass used in residential or commercial building. It is made of two sheets of glass or more with PVB or SGP. Laminated Glass can resist impact by pieces of metal and rocks. That makes it have the property of stealing-resistant and glass anti-splash. It is one kind of shatter resistant materials and its shattered glass does not t break into pieces. That is why it is called safety glass.Besides,our Laminated glass can be energy efficiency to save your bill, acoustic to help you reduce outdoor noise, or even hurricane-resistant with SGP Interlayer. The two sheets of glass or more can be annealed, tempered, heat strengthened and ceramic frit. They can also be float glass, patterned glass,low e, silver mirror and painted glass.

Laminated Glass Test |  Laminated Glass Test Result |  Laminated Mirror Test Result |

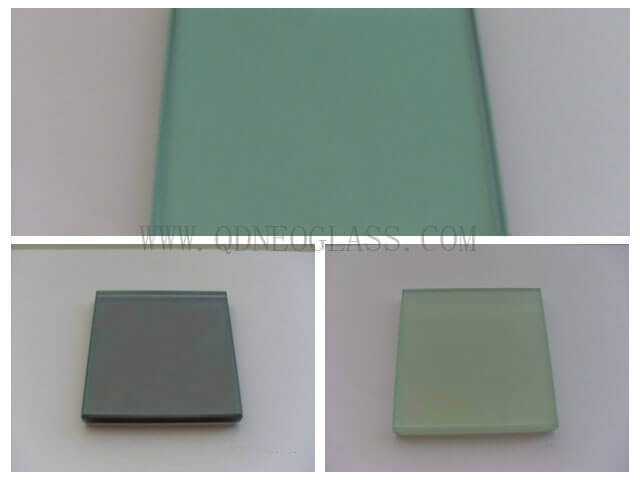

Color Available

Due to the color of Float Glass or Glass Interlayer , Laminated Glass is available with various of colors besides of Clear Laminated Glass, such as White Translucent, Grey, Euro Grey, Dark Grey, Bronze, Blue, Dark Blue, Light Blue, Fordblue, Green, Light Green etc. PVB is available in different colors, that solve the availability limit of Tint Float Glass and makes Laminated Glass more colorful.

Tint Laminated Glass Series |  Grey Laminated Glass |  Bronze Laminated Glass |  Black & Milky Laminated Glass |

Custom-Made Laminated Glass

We not only do Custom-Made Color Laminated Glass, we also do Laminated safety glass at Custom-Made Size, Shape and Make-up. For example, Polished Laminated Glass, Cut To size Laminated Glass, Round/Irreguar Shape Laminated Glass, Tempered Laminated Glass, Heat Strengthened Laminated Glass are all avaiable.

Besides of common Laminated Glass, Acoustic Laminated Glass, Anti-UV Laminated Glass, Energy-Efficiency Laminated Glass & SGP Tempered LaminatedbGlass (Anti-hurricane Glass) are all avaiable.

White Translucent Laminated Glass Panels (Also called Milky White & Frosted) |  -Rough Edgework |

-Blue Reflective Color |

Production Process

Laminated Glass is processed mainly in three period. First of all, Pre-Laminating two sheets or more sheets of glass with PVB or SGP; Then Cooking Pre-Laminated Glass on Autoclave with Pressure about 13 PA and High Temperature around 135℃ ; the last step is Packing.If it is Tempered Laminated Glass or Heat Strengthened Laminated Glass, certainly the glass should be fully toughened or semi-Tempered firstly before pre-laminating. The Tempered Glass conbining to Laminated Glass can be processed with Polished Edges,Holes, Cut-Outs or in Irregular Shape.

Feature

I. Longer Lifetime, Less de-Lamination Rate

II. High Quality of Raw Glass and PVB & Ionoplast Interlayer (SGP)

III. Flat items with Good Flatness control within 0.2%, even within 0.1% for small cut to size items

IV.Size Tolerance controlled:

Within 1mm for Cut To Size and Raw Glass size( same color glass);

Within 1mm for Cut To Size items 2000mm with Grinded Edges;

Within 1.5mm for Cut To Size Items 3000mm with Grinded Edges;

V. Strict Control on Visible Defects and Chips

VI.Solutions of Breakage Problem in Transportation:

Unique Professional & Stonge package

--Plywood End Cap ,Plywood crate, Plywood A Frame, Metal Package etc;

Container Loaded technology

VII.Thickness: 4.35-32.28mm;

Size: Cut to Size, Custom-made, Max 18000mm

Application

Laminated glass can be used as Curtain Wall, Door & Window, Roof, Balcony, Balustrade, Partition,Step,Table, Cabinet, Wardrobe,wherever you would like to use.

With certificates of AS/NZS 2208: 1996 and CE, the glass is popular in Australia, New Zealand Market, Europe, USA, Canada and South of America

|  |  |

|  |  |